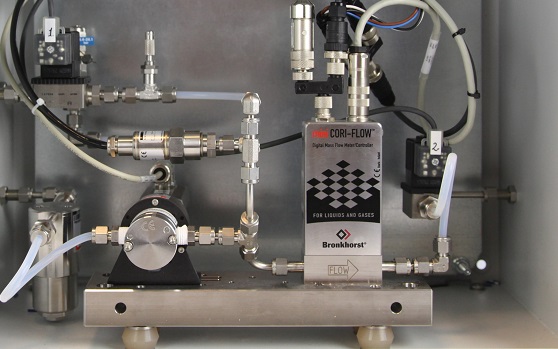

Coriolis mass flow meter in modular dosing system

A metering pump can be used to move a volume of liquid in a specific period of time. Users often believe this provides them an accurate pumped volume. However, there are some disadvantages of using only metering pumps without a flow meter. In this blog, I will share the details with you.

Why do you need a flow meter if you use a metering pump?

Traditionally, metering pumps are believed to be accurate because the theory is that a known pump head displacement will move a known volume over a known time giving a known delivered flow. In practice, however, it will never achieve a high level of accuracy.