Easy switching of gas types

As air, oxygen, nitrogen and carbon dioxide are the most common gases in this field, the FLEXI-FLOW Compact has the data on these gases available in an on-board database, so there is no need for additional calibration. Using the on-board FLUIDAT firmware, the instrument instantly calculates the physical properties of gases and adjusts accordingly, allowing you to reduce the number of instrument types needed.

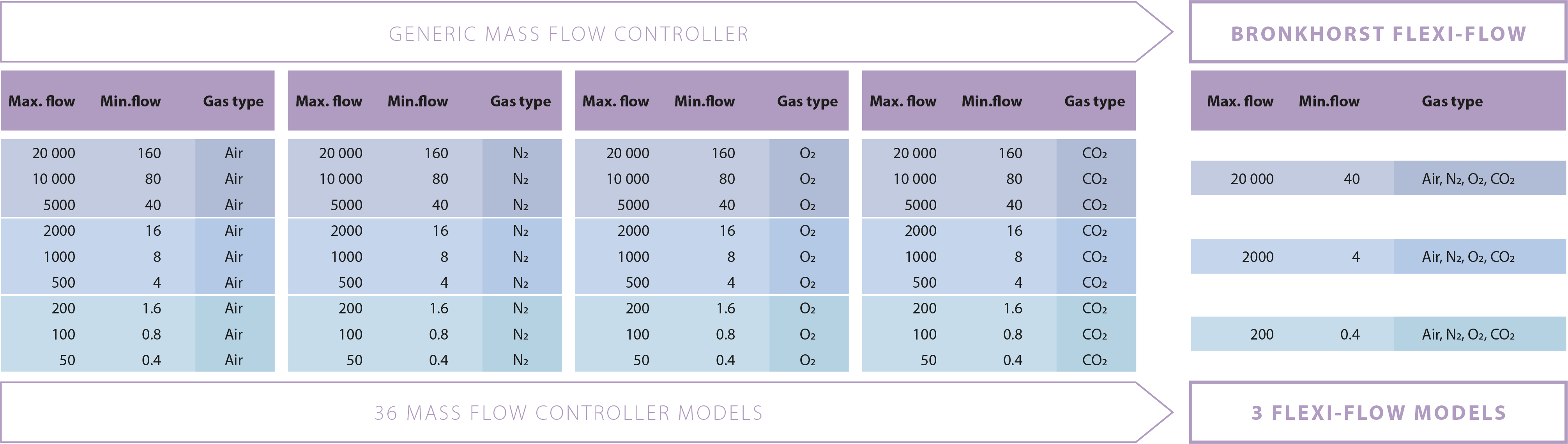

Where a typical range up to 20 ln/min with four gases has been traditionally covered by 36 MFC models, this can be reduced to 12 models, and with four gases on board even to 3 mass flow controller models. The bioreactor manufacturer and the end-user can decide which of these gases to use by setting a parameter in the software.

Reduction of gas flow controllers possible